The Ngerengere Village in Morogoro rural is surrounded by Maasai who are pastoralists. They are highly dependent on cattle for their livelihood, including milk, which is one of the major sources of income to the Maasai women. Naturally, with a huge cattle population, the production of milk was very high. However, during rainy seasons there was no reliable market for the Maasai to sell the milk. Therefore, they opted not to milk their cows.

Identifying a business opportunity, three graduates: Victor Mfinanga, Florent Nguma and Samwel Massawe from Sokoine University of Agriculture, started a milk company called Shambani Graduate Enterprises in 2003. They started collecting milk by installing a Milk Cooling Tank, training the milk producers on best dairy farming practises, and processing dairy products. This created a reliable market for the milk producers, the Maasai. Soon, other community members who are not the Maasai also started rearing dairy cows.

Later rebranded as Shambani Milk Company, the business has been working closely with GAIN through the SUN Business Network, Keeping Food Markets Working (KFMW) programme and GAIN’s Access to Better Dairy Greening Project in providing both technical assistance (capacity building/trainings on food safety and business development) and financial support ( including provision of grant and facilitating linkages to commercial funding) to strengthen its role in increasing the consumption and production of nutritious food specifically dairy products in the community.

Naturally, with a huge cattle population, the production of milk was very high. However, during rainy seasons there was no reliable market for the Maasai to sell the milk. Therefore, they opted not to milk their cows. © GAIN

Due to challenges the community faced in consuming nutritious products particularly dairy products as well as food safety issues, the company observed many children suffering from malnutrition in the village. Though there was plenty of milk produced in that area, it was sold under poor hygienic conditions (milk sold as raw milk and sometimes adulterated).

As a result, Shambani Milk Company identified an opportunity to add value and ensure customers get quality and hygienic milk by establishing a milk processing plant with one milk supplier; at a processing capacity of 30 litres of milk per day; producing only one product fermented milk (mtindi). Currently the company has installed new machines of 1,000lts capacity per hour, producing more than four products and, offering permanent employment to more than 20 people (80% youth) who engage with more than 300 milk suppliers, 90% being the Maasai women.

Safe, affordable, accessible milk products

Shambani Milk is reaching lower income consumers with safe and healthy products and distributes small size pack of 250ml and 500 ml that are being sold in Mangi shop (local shops) at less than 1 dollar through retailer shops located the region of Morogoro, Dar es salaam and Dodoma.

Previously, there were challenges around improving quality control measures particularly on product spoilage and spillage which was caused by human error, specifically cross contamination and machine breakdown. Moreover, there were gaps in record keeping that made it difficult to trace product issues and customer complaints.

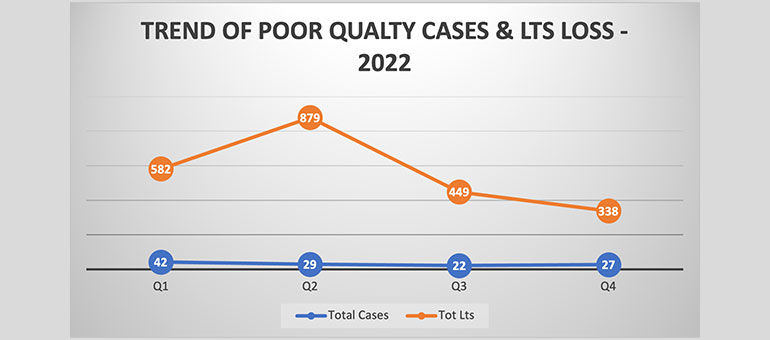

As a result, during the first two quarters, 65% of milk collected was reported as spoilage from various cases, compared to only 15% of milk reported at the end of quarter 4 of 2022. Furthermore, the trend of handling poor milk cases and losses has been reducing significantly from the beginning of the FY 2022 to end of FY 2022 as shown below.

The trend of handling poor milk cases and losses has been reducing significantly from the beginning of the FY 2022 to end of FY 2022. © GAIN

To further reinforce the gains realized, it was equally important to adopt a food safety culture in the factory and make it as part and parcel of staff daily implementation activities. Moreover, frequent trainings, daily morning meeting reminders and monitoring was emphasized, for example, introducing commitment form by the human resource department to every staff to sign, making a commitment to abide by food safety regulations.

Most importantly, GAIN has continued to work with the company to provide technical recommendations on how they can further improve the quality of milk. This has included implementing several quality control systems that have greatly streamlined business functions, and improved efficiency. Overall, the strategic outlook for Shambani Milk Company is to be the first ISO 22000 certified dairy processing company offering best quality product and services.