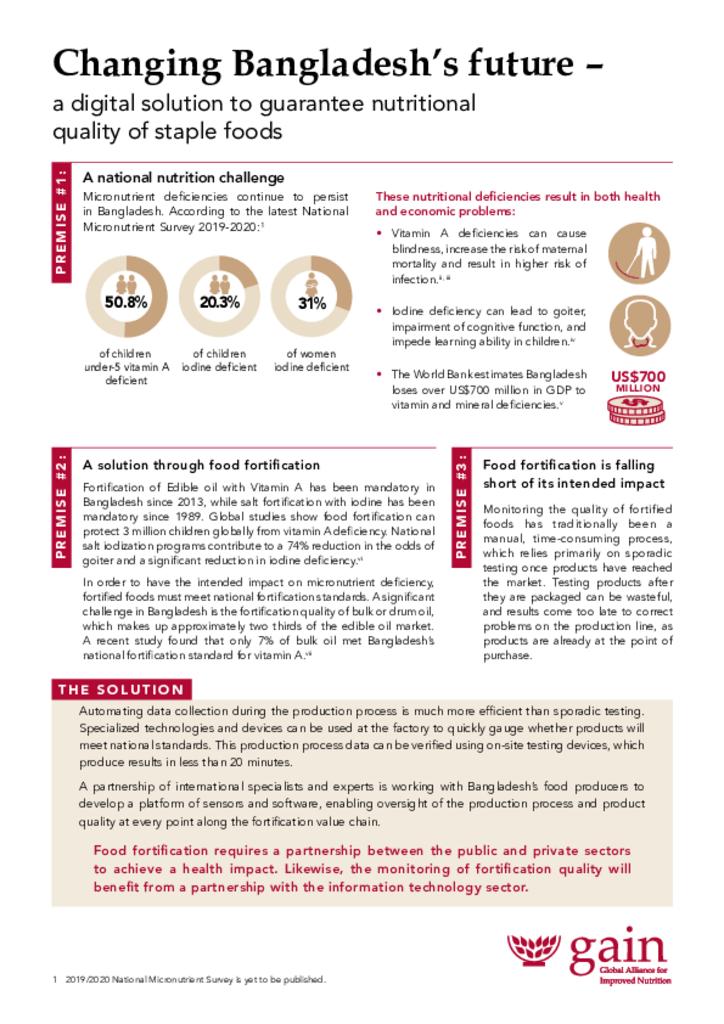

Monitoring the quality of fortified foods has traditionally been a manual, time-consuming process, which relies primarily on sporadic testing once products have reached the market. Testing products after they are packaged can be wasteful, and results come too late to correct problems on the production line, as products are already at the point of purchase.

Automating data collection during the production process is much more efficient than sporadic testing.

Specialized technologies and devices can be used at the factory to quickly gauge whether products will meet national standards. This production process data can be verified using on-site testing devices, which produce results in less than 20 minutes.

A partnership of international specialists and experts is working with Bangladesh’s food producers to develop a platform of sensors and software, enabling oversight of the production process and product quality at every point along the fortification value chain.